-600x600.jpg)

-600x600.jpg)

-80x80.jpg)

-80x80.jpg)

Product in category: Exhaust System - V band clamp and hose clamp

- Stock: In Stock

- Reward Points: 2

- Model: EP-HFQ81

- Weight: 0.20kg

You are buying on 100% Brand New of:

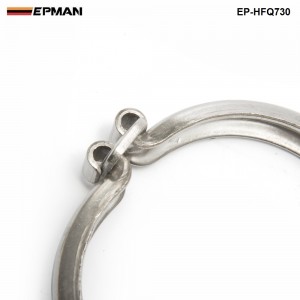

EPMAN Turbocharger Turbine Exhaust Cartridge Clamp V-Band Turbo 81MM Flange EP-HFQ81

This

clamp is used to clamp up the V-band style flanges of the bearing

housing and the turbine housing flanges for Toyota CT12 and For GT30

Turbochargers (as well as others) as used on many vehicles.

Specifications:

Outside Diameter 81.2mm

Assembled Size (Flange Size) 78.0mm

Flange Clamping Thickness 14.0mm

Maximum Torque Setting 5NM (Newton Metres).

Material:Stainless steel 304

These clamps are complete and include fixing bolt and nut.

Applications:

For TOYOTA CT12

Turbocharger Model CT30 (as well as other) on many vehicles

Kit Includes:

1 x Turbo Adapter Flange

CORRECT TIGHTENING OF YOUR V-BAND CLAMP:

Correct fitting of a V-band clamp is vital for correct operation and to ensure you do not suffer premature failure.

V-Band

clamps are NOT tightened excessively. They are designed to pinch the

mating flanges together whilst allowing movement through expansion and

vibration. Over-tightening can damage clamps, flanges and in worst case

pipe work.

To

mount your V Band clamp, butt mating flanges together and fit clamp.

Tighten clamp to a torque setting of 3.5 Newton Metres (NM). Then using a

rubber mallet, tap around the mating flanges to allow the joints to

fully centre and sit without any unequal load. Then increase torque to

its final torque setting of 5 Newton Metres (NM).

Further

tapping with a rubber mallet to removing any uneven load from the clamp

or flange is beneficial whilst checking the torque setting stays at

its rating of 5 Newton Metres (NM).

**************WE HIGHLY RECOMMEND PROFESSIONAL INSTALLATION!***************

*No installation Tool & No instruction is Included, Professional Installation is Recommended*

All

items are Brand New unless stated otherwise on the listing. We sell DIY

(Do It Yourself) Items with a few exceptions. We take no responsibility

in teaching you how to install. Professional installation is strongly

recommended.

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)